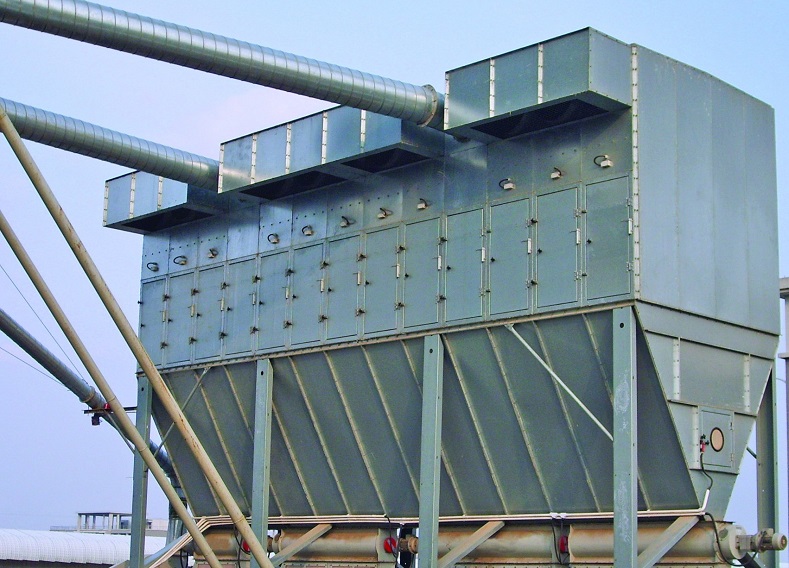

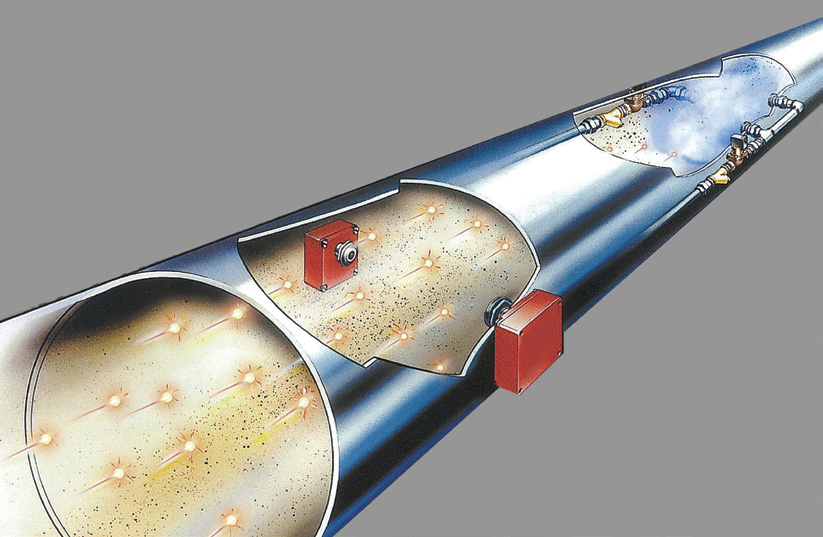

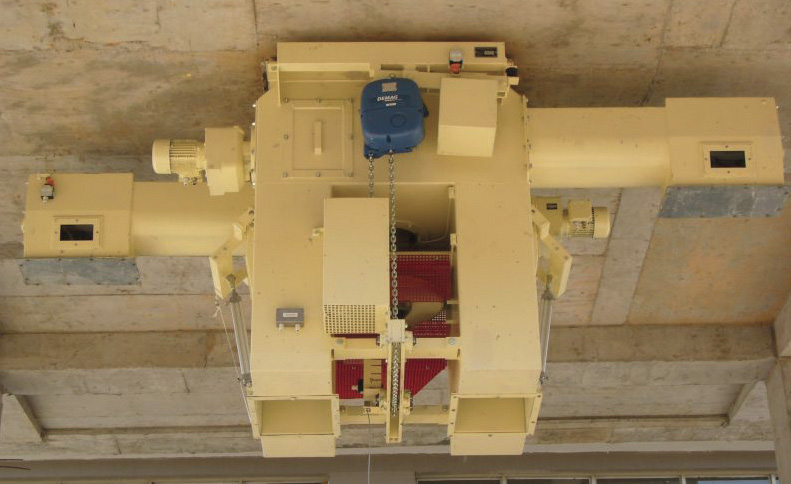

Our High Load (LHL) Filter System is a modular designed filter system for the continuous filtration of fine sanding dust, shavings, chips, fibres, and mineral wool. This system allows easy future expansion and flexibility, while ensuring reliable and stable operations within the factory. Coupled with our efficient cleaning system and highly efficient fans, our LHL Filter System guarantees considerable energy savings with low energy consumption and minimum maintenance cost.

Specially designed for high loadings and high pressure cleaning, Our LHL Filter System is available in both positive and negative pressure systems. The extracted warm air can be 100% recycled to the production sites.

Our High Load (LHL) Filter System is a modular designed filter system for the continuous filtration of fine sanding dust, shavings, chips, fibres, and mineral wool. This system allows easy future expansion and flexibility, while ensuring reliable and stable operations within the factory. Coupled with our efficient cleaning system and highly efficient fans, our LHL Filter System guarantees considerable energy savings with low energy consumption and minimum maintenance cost.

Specially designed for high loadings and high pressure cleaning, Our LHL Filter System is available in both positive and negative pressure systems. The extracted warm air can be 100% recycled to the production sites.

Our High Load (LHL) Filter System is a modular designed filter system for the continuous filtration of fine sanding dust, shavings, chips, fibres, and mineral wool. This system allows easy future expansion and flexibility, while ensuring reliable and stable operations within the factory. Coupled with our efficient cleaning system and highly efficient fans, our LHL Filter System guarantees considerable energy savings with low energy consumption and minimum maintenance cost.

Specially designed for high loadings and high pressure cleaning, Our LHL Filter System is available in both positive and negative pressure systems. The extracted warm air can be 100% recycled to the production sites.

Our High Load (LHL) Filter System is a modular designed filter system for the continuous filtration of fine sanding dust, shavings, chips, fibres, and mineral wool. This system allows easy future expansion and flexibility, while ensuring reliable and stable operations within the factory. Coupled with our efficient cleaning system and highly efficient fans, our LHL Filter System guarantees considerable energy savings with low energy consumption and minimum maintenance cost.

Specially designed for high loadings and high pressure cleaning, Our LHL Filter System is available in both positive and negative pressure systems. The extracted warm air can be 100% recycled to the production sites.

Our High Load (LHL) Filter System is a modular designed filter system for the continuous filtration of fine sanding dust, shavings, chips, fibres, and mineral wool. This system allows easy future expansion and flexibility, while ensuring reliable and stable operations within the factory. Coupled with our efficient cleaning system and highly efficient fans, our LHL Filter System guarantees considerable energy savings with low energy consumption and minimum maintenance cost.

Specially designed for high loadings and high pressure cleaning, Our LHL Filter System is available in both positive and negative pressure systems. The extracted warm air can be 100% recycled to the production sites.

Our High Load (LHL) Filter System is a modular designed filter system for the continuous filtration of fine sanding dust, shavings, chips, fibres, and mineral wool. This system allows easy future expansion and flexibility, while ensuring reliable and stable operations within the factory. Coupled with our efficient cleaning system and highly efficient fans, our LHL Filter System guarantees considerable energy savings with low energy consumption and minimum maintenance cost.

Specially designed for high loadings and high pressure cleaning, Our LHL Filter System is available in both positive and negative pressure systems. The extracted warm air can be 100% recycled to the production sites.

Our High Load (LHL) Filter System is a modular designed filter system for the continuous filtration of fine sanding dust, shavings, chips, fibres, and mineral wool. This system allows easy future expansion and flexibility, while ensuring reliable and stable operations within the factory. Coupled with our efficient cleaning system and highly efficient fans, our LHL Filter System guarantees considerable energy savings with low energy consumption and minimum maintenance cost.

Specially designed for high loadings and high pressure cleaning, Our LHL Filter System is available in both positive and negative pressure systems. The extracted warm air can be 100% recycled to the production sites.